The aerospace giant Boeing has completed an $8.4 billion acquisition of a key supplier of aircraft parts known as Spirit AeroSystems. The deal marks the end of a foray by Boeing to outsource production of fuselages for its bestselling Boeing 737 and 787 Dreamliner aircraft to cheaper third-party vendors.

Spirit AeroSystems was the supplier of a so-called ‘mid cabin exit plug’ that suffered an explosive blowout on an Alaska Airlines Boeing 737MAX in January 2024.

- Boeing takes production of key aircraft components in-house

- Airbus will be compensated $439 million by Boeing for taking on suppliers

- Boeing will take 15,000 new employees onboard as part of the deal

- Decision stemmed from the Alaska Airlines exit door blowout in January 2024

- Alaska Airlines was sending its own inspectors to Boeing’s production lines because it was so concerned about workmanship

- Bottom line

Boeing takes production of key aircraft components in-house

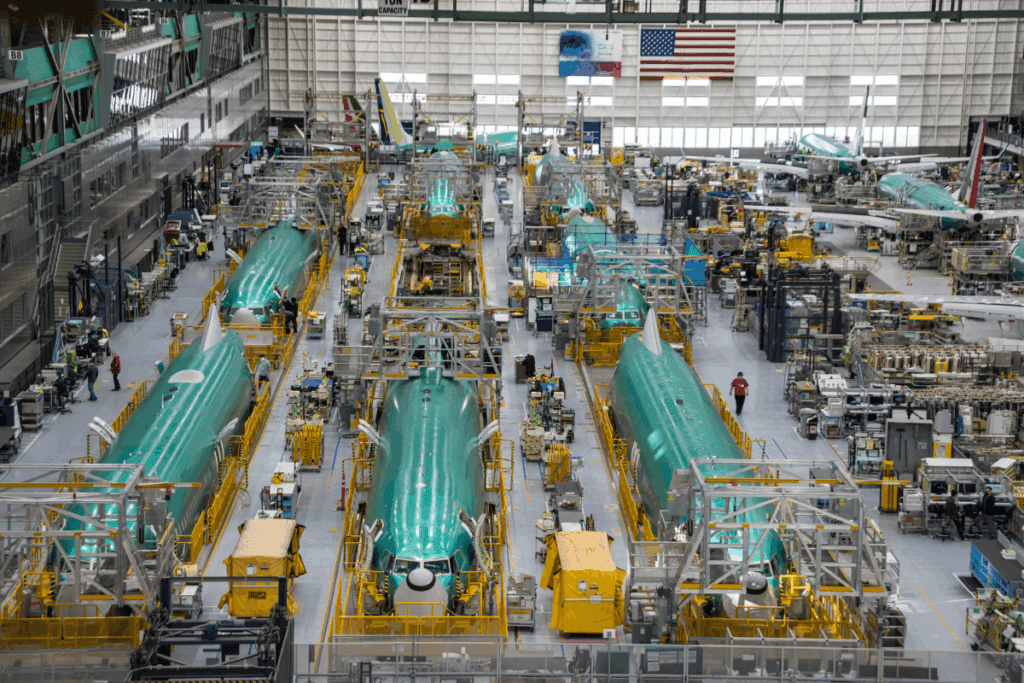

Boeing first announced it planned to buy Spirit AeroSystems in July 2024 in an $8.4 billion deal that would bring all of Spirit’s Boeing-related commercial operations in-house for the first time in two decades.

Spirit AeroSystems was created in 2005 when Boeing decided to sell off its own manufacturing plants in Wichita, Kansas, and Tulsa, Oklahoma, forming an independent company that would supply Boeing, as well as other aerospace players, including arch rival Airbus.

Following years of controversy over shoddy workmanship and declining production standards, Boeing decided that the best way to raise standards to where they needed to be was to buy back Spirit AeroSystems.

The deal did not, however, come cheap. Boeing sold its plants for an estimated $1.2 billion but had to buy back Spirit for $8.3 billion, which included $4.7 billion in equity and all of Spirit’s debts.

On Monday, Boeing announced it had finally finalized the acquisition of Spirit, which includes all of Spirit’s Boeing-related commercial operations.

In a statement, Boeing said the deal “also brings Boeing’s largest supplier of spare parts in-house, expands Boeing’s global maintenance, repair and overhaul services footprint, and adds to Boeing’s rotable, lease, and exchange portfolio with Spirit’s aftermarket businesses.”

Airbus will be compensated $439 million by Boeing for taking on suppliers

Given that Spirit AeroSystems has expanded into a global supplier of aircraft parts, what is known as an Original Equipment Manufacturer, Boeing couldn’t simply just repurchase the plants in North America it sold 20 years ago.

Today, Spirit is also a major supplier to rival aircraft manufacturer Airbus, so when Boeing decided it wanted to bring the parts of Spirit that supplied its production lines, it had to strike a deal with Airbus as well.

The deal involved Airbus taking direct responsibility for a slew of Spirit sites around the world, including in Kinston, North Carolina, where A350 fuselage sections are made, and Casablanca, Morocco, where parts for its A321 and A220 models are built.

Boeing agreed to compensate Airbus $439 million to take on these facilities, although that’s less than the estimated compensation of $559 million that was floated when the deal was first announced last Summer.

Boeing will take 15,000 new employees onboard as part of the deal

Today’s deal will see Boeing integrate Spirit’s commercial and aftermarket operations in:

- Wichita, Kansas

- Dallas, Texas

- Tulsa, Oklahoma

- As well as Spirit’s Aerospace Innovation Center in Prestwick, Scotland.

Around 15,000 of Spirit’s employees will now transfer to Boeing.

Some of Spirit’s operations are not, however, being brought completely in-house. Spirit Defense will remain an independent supplier to the industry, while Spirit’s facility in Belfast, Northern Ireland, will operate as an independent subsidiary branded as Short Brothers, a Boeing Company.

Decision stemmed from the Alaska Airlines exit door blowout in January 2024

Although Boeing had been battling workmanship and quality control issues at Spirit for some time, the final straw on the camel’s back was the mid-exit plug blowout on Alaska Airlines flight AS-1282 on January 5, 2025.

Shortly after takeoff from Portland International Airport, the almost brand-new Boeing 737MAX-9 jet suffered an explosive decompression when the exit plug suddenly blew out as the plane reached a critical altitude.

Thankfully, only three of the 171 passengers and 6 crew members on board the plane suffered minor injuries.

The exit plug had been manufactured by Spirit AeroSystems in Malaysia and then shipped to Spirit’s facility in Wichita, where it was installed in the aircraft’s fuselage. The fuselage section was then sent by train to Boeing’s final production line in Renton, Washington, where five damaged rivets were found near the exit plug.

The plug had to be removed so that Spirit’s engineers could fix the rivets. Once the rivets were fixed, the exit plug was reinstalled but never bolted securely back into place.

Alaska Airlines was sending its own inspectors to Boeing’s production lines because it was so concerned about workmanship

In January, Alaska Airlines revealed that it had been forced to station its own team of inspectors at Boeing’s Renton factory to ensure new airplanes destined to join the carrier’s fleet are up to standard.

A team of three of the airline’s Aircraft Acquisition Representatives now spend five days a week on-site in Renton, and its team had been further ‘augmented’ with three specialist Maintenance and Engineering employees to improve oversight of Boeing’s production processes.

If that wasn’t enough oversight, Alaska Airlines also said it had hired third-party inspectors from Ausgael Aviation Services to provide an additional audit service at the Renton factory seven days per week.

Bottom line

Boeing’s chief executive and president, Kelly Ortberg, said on Monday that the acquisition of Spirit AeroSystems was a “pivotal moment in Boeing’s history and future success.”

Ortberg continued: “As we welcome our new teammates and bring our two companies together, our focus is on maintaining stability so we can continue delivering high-quality airplanes, differentiated services, and advanced defense capabilities for our customers and the industry.”

Years of outsourcing and cost cuts led to this moment – an admission by Boeing that it had let quality standards slip as its focus on safety slipped in favor of chasing profits.

Boeing will no doubt be hoping that bringing production in-house will not only improve workmanship but also signal to the industry and flying public that it’s serious about improving standards.

Related

Mateusz Maszczynski honed his skills as an international flight attendant at the most prominent airline in the Middle East and has been flying ever since... most recently for a well known European airline. Matt is passionate about the aviation industry and has become an expert in passenger experience and human-centric stories. Always keeping an ear close to the ground, Matt's industry insights, analysis and news coverage is frequently relied upon by some of the biggest names in journalism.